Featured Projects

Masonry Material Industry Client

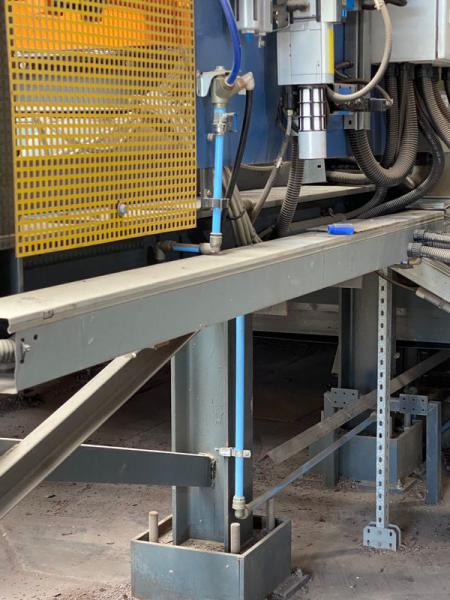

Piping Solution, Above and Below

This client was increasing their productivity by adding new robotic technology to their facility. Initial concept for the compressed air piping by the client was to use carbon steel piping, install the new air lines above, and drop down to all production floor locations. After site review and meetings we proposed our solution. The most cost-effective plan would be to drop the air lines down in fewer locations, install most delivery pipe underneath the new robots, and to use non-corrosive aluminum compressed air piping.

We explained to the client the benefits of the Infinity Quick-Lock aluminum piping system. Innovative design with the performance of heavy, traditional steel piping, at the cost of systems using plastic. Secured by nickel-plated brass fittings that provide the deepest level of engagement. Revolutionary lock-and-seal design ensures a totally safe, leak-free system for all compressed air, vacuum, nitrogen and inert gas applications. Easily connected to existing piping networks and simple to modify for any future expansions or changes. All while having the lowest total cost of ownership over time compared to other piping systems.

Client agreed to our solution. Approximately 450’ of 50mm (2”), 25mm (1”), and 14mm (1/2”) pipe and fittings were installed. Client was pleased with the quick turnaround of the project and the clean look of the new compressed air piping.

Contact us anytime for service, sales, or assistance with your project.

512-563-8332

512-986-2828

Se habla espanol 512-986-2828

jandrelectromechanical@gmail.com

811B Tradesmens Park Loop

Hutto, TX 78634