Featured Projects

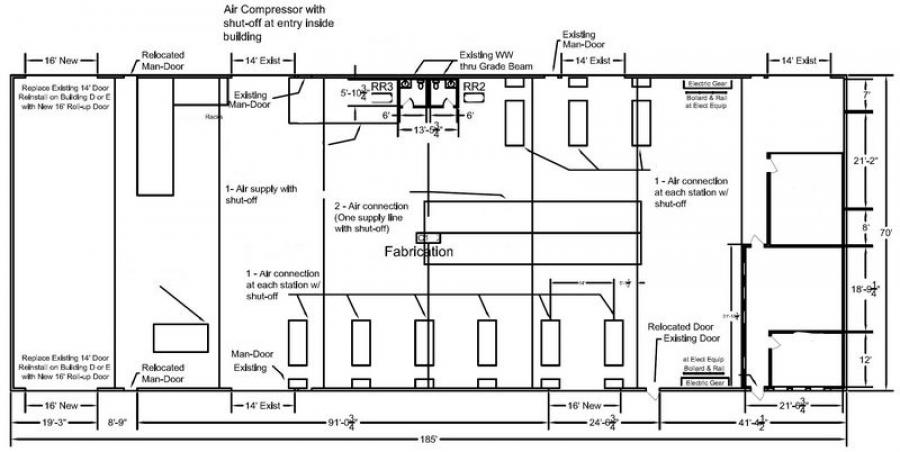

Fabrication Facility Client

Fast & Flexible Design and Installation

This client was expanding and wanted to keep the Mattei brand they have had for years. Client expressed interest in energy savings so the Variable Speed Drive (VSD) Mattei Blade Rotary Vane series of air compressors was chosen.

This design-build project included the design, equipment selection, procurement, installation, and commissioning of the compressed air system. After determining the compressed air consumption from all equipment and tool requirements, the energy saving Mattei Blade 22i (30 HP) was selected. Mattei’s BLADE i range of VSD compressors can match their operation to suit the load profile required by the compressed air system. The inverter adjusts the motor’s rotational speed, adapting the air delivered by the compressor to the real demand. The BLADE i series can save up to 35% of the annual operating costs versus other compressors. To complete the system and provide clean dry quality air, we installed a Hankison FLX series cycling refrigerated air dryer, Hankison Pre and After filters, Beko Qwik-Pure condensate treatment system, Beko zero loss automatic condensate drain, and a 240 gallon air receiver tank.

The AirNet system was used for the compressed air piping. Roughly 500’ of 40mm (1 1/2”) pipe was installed for the main header loop along with 13 drops to production in 20mm (3/4”) pipe. Every drop was terminated with a shutoff valve for safety.

This project demonstrated some of the capabilities we can provide to clients. We can execute the delivery of your design-build, from scope of supply definition and design assistance to installation and equipment preventive maintenance agreements. With a design-build project from J&R Electromechanical, we can be flexible to fast track your schedule, help control costs, and complete the job safely on time and budget.

Contact us anytime for service, sales, or assistance with your project.

512-563-8332

512-986-2828

Se habla espanol 512-986-2828

jandrelectromechanical@gmail.com

811B Tradesmens Park Loop

Hutto, TX 78634